In this article, we\'ll find out how a turbocharger increases the facility output of associate engine whereas living extreme operational conditions. We\'ll conjointly find out how wastegates, ceramic rotary engine blades and ball bearings facilitate turbochargers do their job even better. Turbochargers area unit a kind of forced induction system. They compress the air flowing into the engine (see however car Engines Work for an outline of airflow in a very normal engine). The advantage of pressure the air is that it lets the engine squeeze more air into a cylinder, and more air means more fuel are often added . Therefore, you get more power from every explosion in every cylinder. A turbocharged engine produces more power overall than constant engine without the charging. this can considerably improve the power-to-weight ratio for the engine (see however power unit Works for details).

In order to realize this boost, the turbocharger uses the exhaust ensue the engine to spin a rotary engine, that successively spins associate air pump. The rotary engine within the turbocharger spins at speeds of up to one hundred fifty,thousand rotations per minute (rpm) -- that is concerning thirty times faster than most car engines can go. And since it\'s connected to the exhaust, the temperatures within the rotary engine also are very high.

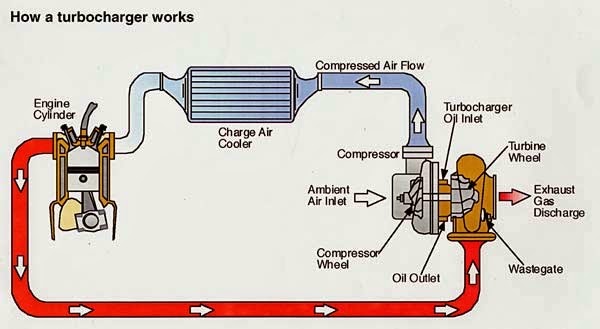

A turbocharger is a device driven by exhaust gases that increases engine power by pumping air into the combustion chambers.

Combustion is limited not by the number of fuel that can be injected but by the number of air associate engine can gulp in to mix therewith fuel. Forcing air into associate engine’s intake manifold at higher-than-atmospheric pressure permits more fuel to be burned, which ends in higher output. The connected supercharger conjointly compresses intake air but is driven by a belt, chain or gears. To oversimplify, the turbocharger employs 2 incased fans mounted on either end of a common shaft. The engine’s exhaust gases area unit routed through one fan, known as the rotary engine, that rotates the shaft. This, in turn, spins the alternative fan, known as the mechanical device, that compresses the air coming into the engine’s intake manifold.

Turbo associated superchargers typically work in bicycle-built-for-two with an intercooler, that serves to chill the compressed gas before it enters the engine. pressure the air heats it, that makes it less dense and negates some of the positive impact, and will cause pinging or sound. Intercoolers generally area unit easy radiators through that the intake air passes to shed some heat, increasing the density before combustion. The “inter” means between, as intercoolers area unit positioned between the turbo and the intake manifold.

Turbochargers have benefits and disadvantages. the most advantage — that propelled their adoption in production vehicles within the past 20 years — is that they grant power on demand from otherwise efficient, compact, usually four-cylinder engines. The disadvantages embody further price, complexity and, in actual use, turbo lag. Turbo lag is the delay in response that occurs when the driver tromps on the accelerator. The turbo takes a second or 2 (or more) to get up to a speed at that it’s pressure the intake air enough to impact associate output increase. Over the years, attempts to reduce turbo lag have come back principally within the form of twin turbo styles. Nowadays, the mixture of sophisticated computerized engine-management systems and single, low-mass turbines appears to be making great strides for Saab and Audi, among others.

As for the engineering and value factors, turbos generally need the employment of stronger pistons, connecting rods and crankshafts than constant engine without a turbocharger would wish. Turbos generate respectable further heat and cause the engine itself to run hotter, therefore heat-resistant valves and a bigger cooling-system radiator area unit common. The rotary engine could spin at rates higher than 150,000 rpm, which requires associate ample offer of pressurised engine oil, at the side of a higher-volume pump and perhaps associate oil cooler. Heat is one in all oil’s greatest enemies, therefore turbocharged vehicles need shorter oil-change intervals — or a minimum of carry the next probability of injury when the schedule isn’t kept.

Show Konversi KodeHide Konversi Kode Show EmoticonHide Emoticon